Life cycle assessment for energy-efficient and climate-friendly optics production

The Fraunhofer Institute for Production Technology IPT in Aachen, Germany, has developed a process that reduces CO2 emissions in glass and optics production by up to 90 percent. The focus is on conducting a life cycle assessment (LCA), which systematically records the energy requirements and CO2 emissions of the manufacturing processes. This data is used to develop and implement optimization potential. Fraunhofer IPT is the only research institute in Europe to offer comprehensive analyses and research on the subject of LCA in optics production.

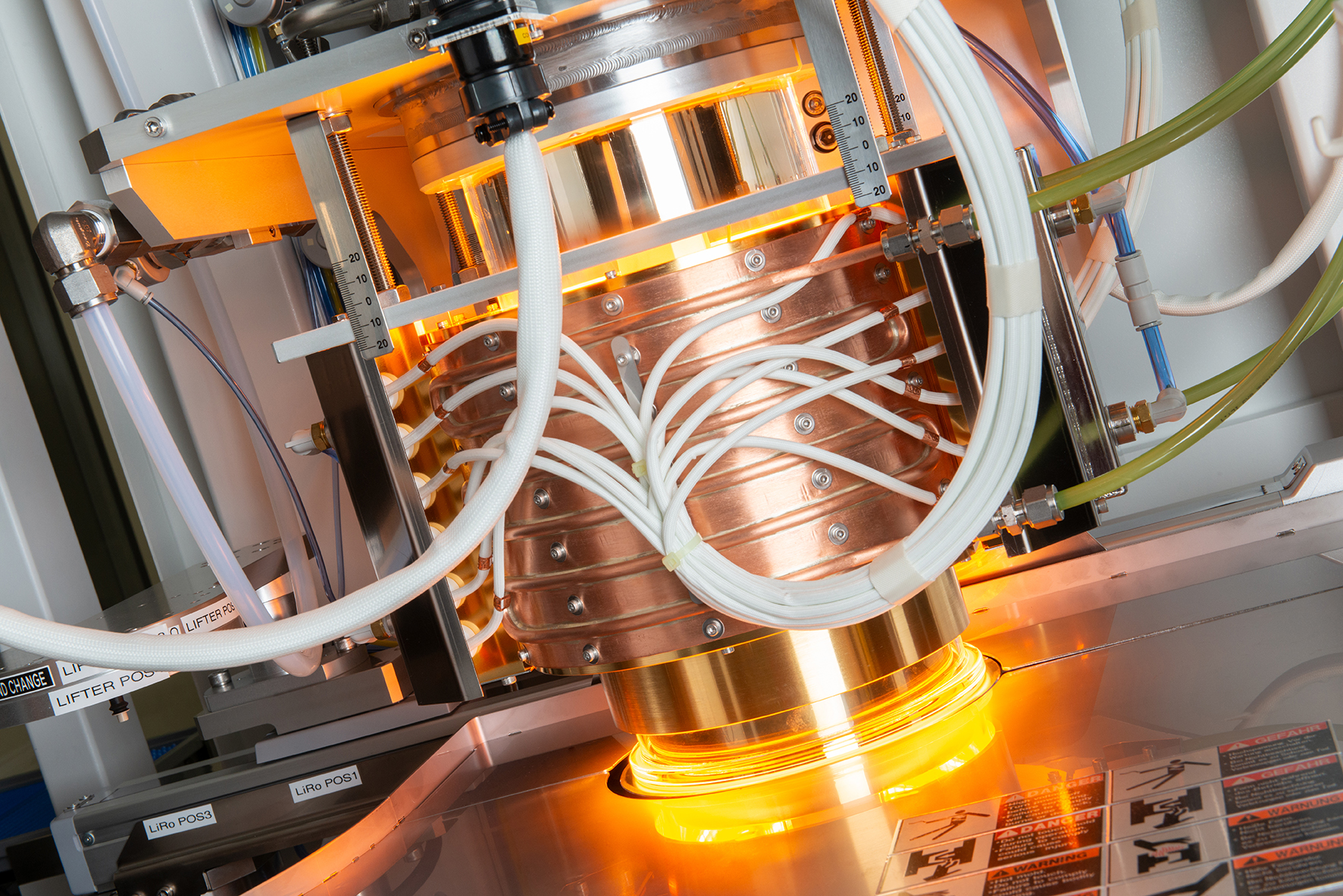

The production of optics made of glass is energy-intensive and causes considerable greenhouse gas emissions. The optics industry must drastically reduce both energy use and CO2 emissions in order to produce economically and at the same time in a climate-friendly manner in an international comparison. But how can the optimization and savings potential in optics production be specifically identified?

Reduction of CO2 emissions by up to 90 percent

Fraunhofer IPT has developed a concept that helps companies save greenhouse gases and energy. The researchers were able to demonstrate this in initial studies: By making targeted changes to the production process chain and optimizing individual processes, they can reduce CO2 emissions during production by up to 90 percent.

Systematic measurement and analysis of the environmental impact of optics production

Fraunhofer IPT’s optimization strategies are based on the results of Life Cycle Assessments, also known as life cycle analysis. The LCA is a method for evaluating the environmental impact of a product or component over its entire life cycle – from raw material extraction to production, use and disposal or recycling. These are among others the carbon footprint, the demand for raw materials and toxicity.

In particular, the production engineers at Fraunhofer IPT are investigating the processes involved in the manufacture of glass optics and recording the energy requirements and CO2 emissions of the individual process steps.

Based on the analyses, the researchers develop tailor-made optimization strategies. They use state-of-the-art digital tools such as machine learning and simulation, as well as experimental approaches to improve blanks, tools and processes.

Customized analysis, consulting and technology roadmaps

Interested companies can take advantage of comprehensive analyses and extensive consulting services to make their processes more climate-friendly. Fraunhofer IPT offers support in the implementation of alternative production process chains and the optimization of individual process steps. In addition, the institute offers consulting services in the field of technology roadmapping that take both economic and ecological aspects into account. Fraunhofer IPT is unique in Europe with this range of services, which are aimed at various sectors such as the automotive industry, consumer electronics, the optical industry and the semiconductor industry.