The requirements for production technology solutions for the aviation industry are increasing significantly due to the growing complexity of the components to be manufactured and the materials used. Today, the demand for sustainable flying and manufacturing needs to consider environmental, social aspects and governance for new developments.

Engines of the future can thus evolve not only towards the use of Sustainable Aviation Fuels (SAFs) but also towards entirely new hydrogen-based propulsion concepts.

Companies must now address strategic questions such as: What will we manufacture in the future? Where will we manufacture it? And how will we do it?

The goal of our research and development activities is to answer these questions together with companies in the aviation industry and their suppliers.

Sustainable Manufacturing and Flying

The traditional "magic triangle" of quality, cost, and time is expanding to include a fourth dimension: sustainability. This requires a closer examination of production cycles and a critical evaluation of the materials used to ensure actions are not only economically but also ecologically and socially responsible.

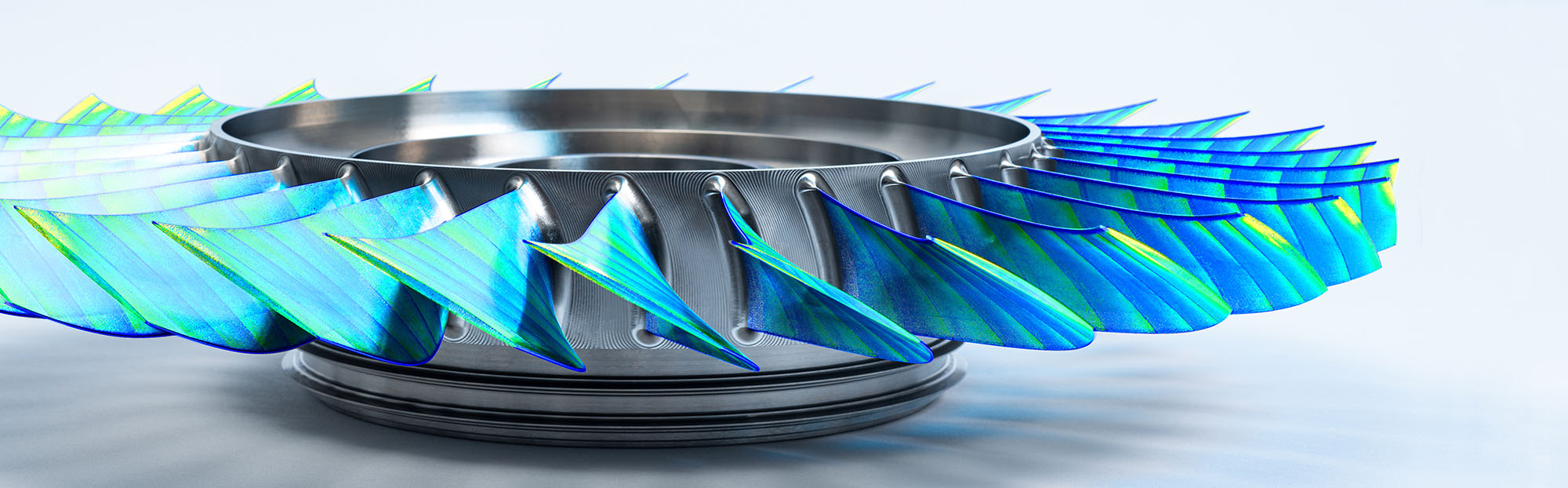

Our research focuses primarily on manufacturing highly sophisticated components and aircraft engines, paving the way for more sustainable aviation enablling higher efficiency and lower emissions.

A Central Pillar of Our Strategy: End-to-End Digitization of the Value Chain

We use digital twins to improve the quality of our production processes, identify potential errors and their causes both before and during production and ensure transparent documentation of all process data.

Digitization enhances transparency and ecological efficiency across the entire process chain, helping us to ensure the integrity of components throughout their entire lifecycle.

Developing New Competencies Together

To achieve our ambitious goals, we work closely with OEMs, suppliers, and research institutions. Within our extensive network, we continuously exchange the latest developments with industry and research partners and offer a wide range of research services – from process design and prototype manufacturing to comprehensive lifecycle analyses.

We invite you to become part of a movement that faces the challenges of the aviation industry together, aiming to make the production of new aircraft engine systems more sustainable.