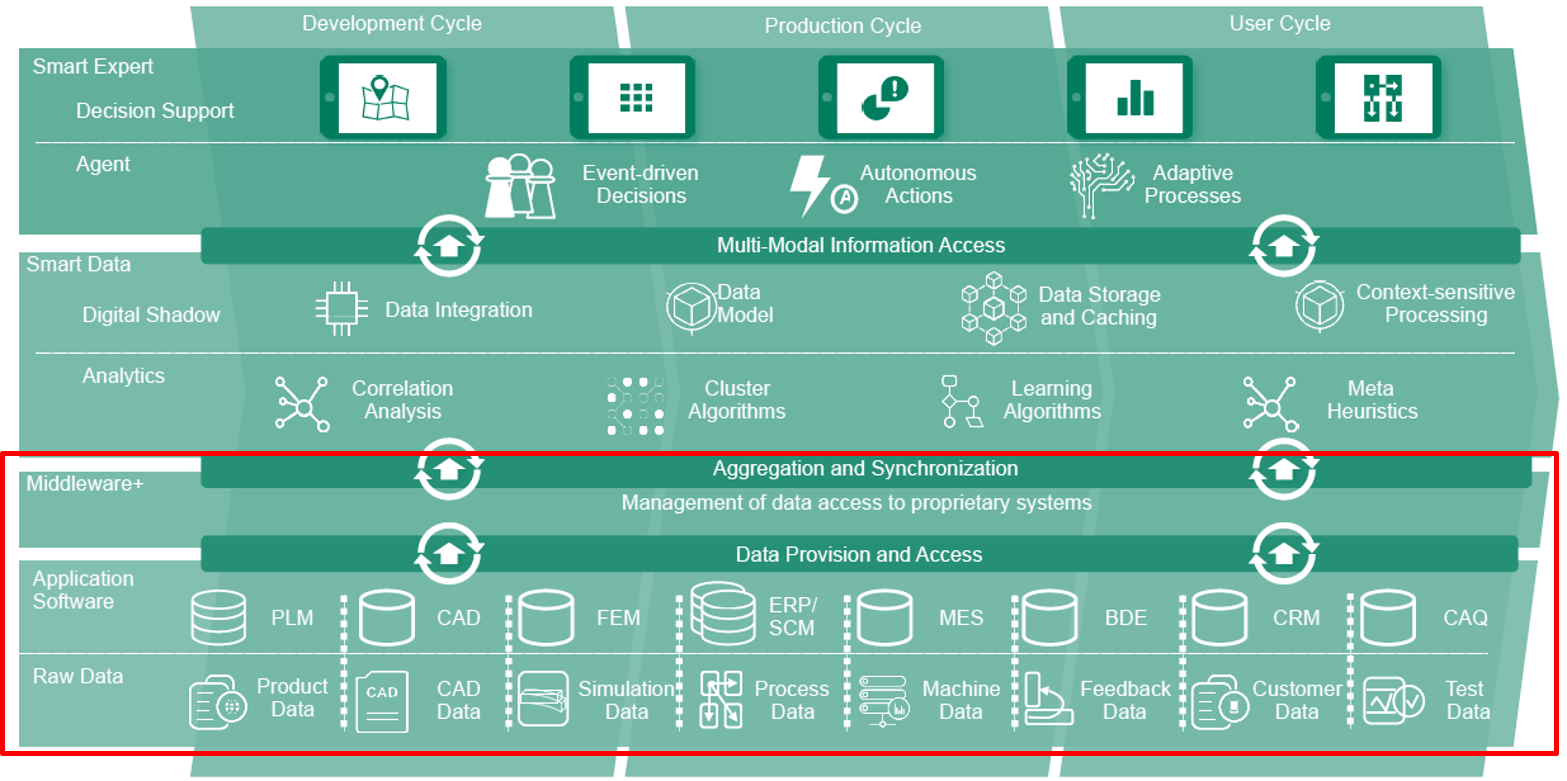

Efficiency, quality and flexibility: The selection of suitable hardware and software systems that accompany the production processes is always the first step. Increasingly complex manufacturing process chains and highly dynamic market developments require a deeper understanding of the manufacturing processes, because machine and measurement data alone is not sufficient. Classic Enterprise Resource Planning (ERP) software is not able to detect unexpected changes, repairs or disruptions in production. Additional software solutions such as Product Lifecycle Management (PLM), Manufacturing Execution System (MES) and Computer-Aided-Quality-System (CAQ) are intended to provide support.

Hardware and software systems

Networked process chains through hardware and software systems

With its many years of experience in manufacturing technology and based on sound methodology, the Fraunhofer IPT selects the right machines and measurement techniques for networked and synchronized process chains. The connection to various software systems creates a basis for consistently usable product, order and quality data. The integration of suitable sensor technology on machines helps to record process data in real time. Efficient interfaces accelerate the communication between the various systems, machines and measuring equipment. On the basis of a complete data basis and real-time production information, error-free and efficient production processes can then be ensured.

Our range of services

- Identification of the need for hardware and software systems for interlinked production

- Support in selecting suitable systems (sensors, actuators, PLM, ERP, ME and CAQ systems)

- Concept development for the integration of systems and definition of interfaces for different systems

- Development of own MES or CAQ modules in research and development projects