Research project "FlexiMill"

The manufacture of geometrically complex metal products relies heavily on the extensive use of five axis-machining operations, supported by advanced computer-aided manufacturing software for process planning. State-of-the-art tool technology used to machine complex geometries, such as freeform surfaces, includes milling with ball end type milling tools. However, the ball end-milling process is very time consuming due to the required small step-over distance between adjacent tool path passes.

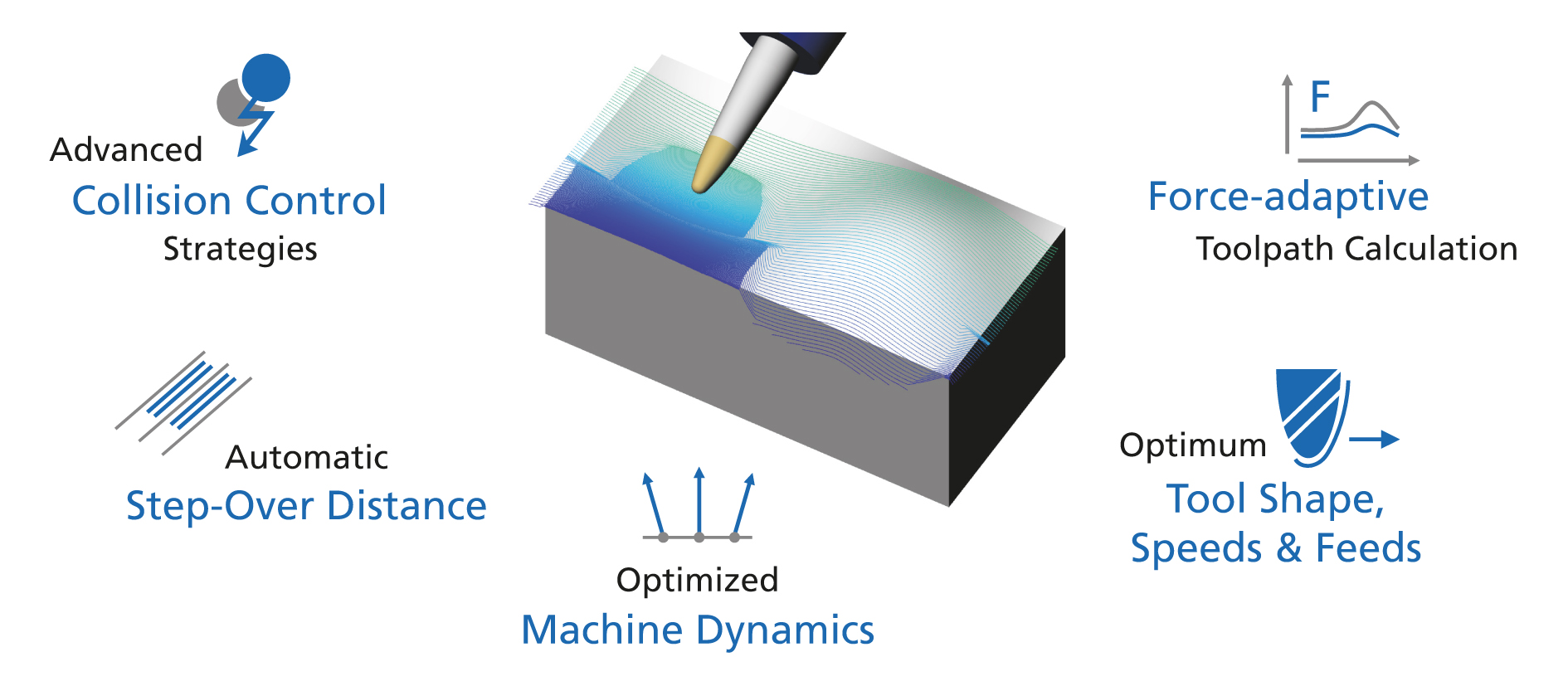

Therefore, the aim of the FlexiMILL project is to develop tailor made innovative and adaptive machining strategies, especially designed for machining complex workpiece geometries with circle segment end mills. As a result, FlexiMILL will enable more flexible use of circle segment end mills in a wide range of applications in businesses ranging from tool and die making and medical industries through to turbo engine manufacturing. The project adopts a threefold approach, addressing the three major research areas “Cutting Tool Technology”, “Process Planning and Toolpath Calculation Technologies” and “Fundamentals and Technology Development”.

Finish milling with barrel tools to speed up cutting time

One approach to increasing productivity in finish milling is to utilize new cutting tool technologies. A major trend in this area is the use of so-called circle segment end mills, also known as barrel tools. Circle segment end mills are characterized by a contour consisting of a circle segment, apparent in the side view, with a considerably larger radius than the actual ball end radius of a comparable ball end mill. Consequently, the step-over distance in finish milling can be increased significantly, resulting in a reduction of the required cutting time by up to 80 percent.

Research Areas

Cutting Tool Technology

Due to the specific cutting conditions prevalent in the milling operations conducted using circle segment end mills, it is crucial that the appropriate tool geometry for a specific machining task is selected carefully at the process planning stage. Appropriate cutting tool design combines a maximum of process efficiency with a high level of geometric flexibility, allowing as large as possible an area of the workpiece to be machined within a short period of time. Once suitable tool geometry is in place, cutting conditions are highly dependent on the combination of tool path and workpiece geometry. The tool design must enable adaptive process control in order to compensate for the influences listed. Finally, it is vital to ensure economic tool life time via classic optimization of cutting-edge geometry, substrate, coating, as well as through optimum speed and feed rates.

Process Planning and Toolpath Calculation

Nowadays manufacturing engineers and technicians can choose from a wide range of machining strategies for a specific machining task. Those strategies are easily implemented via a wide range of commercially available CAM software packages and are industry-proven in numerous applications. However, when it comes to milling complex geometries such as freeform surfaces, strategies usually focus on the point contact of the state-of-the-art ball-end milling process. The simple transfer of such existing machining strategies onto the milling with circle segment end mills is often not sufficient. The eccentric position of the circle segment center point, along with the limitations in tool orientation and the differing cutting conditions require adaption of existing tool path calculation algorithms. FlexiMILL will therefore focus on the development of suitable machining strategies which take account of the mentioned specific characteristics of circle segment end mills. The R&D results will be incorporated into the market-leading multi axis calculation core and in one of the major CAM software products readily available on the market today.

Fundamentals and Technology Development

The cutting conditions in milling, i.e. the engagement between the cutting tool and the workpiece, largely determine the overall performance of the cutting process. In milling operations conducted using circle segment end mills, the resulting cutting conditions are generally different from the point contact, which occurs in milling with ball end mills. As a result, there may be significant variations in the machinability criteria such as cutting force, tool wear, process stability and surface quality within a single process. FlexiMILL will focus on the detailed analysis of cutting conditions in terms of different surface topographies, process parameters and machining strategies, when using circle segment end mills. The goal of these research activities is to deduce adequate process rules and to translate these into viable machining strategies. The innovative approaches in machining strategies will be directly integrated into the tool path calculation core and subsequently into the major CAM software product. Ultimately the developments will be demonstrated within the process planning and machining of a full demonstrator component from the medical sector.

Project Partners

- Camaix GmbH, Eschweiler (D)

- Fraisa SA, Bellach (CH)

- Fraunhofer Institute for Production Technology IPT, Aachen (D)

- Mathys AG, Bettlach (CH)

- ModuleWorks S.R.L., Bucuresti (RO)